Carbon fiberƙarfafa fasahohin sarrafa gadar babbar hanya ta sami tagomashi sosai a cikin 'yan shekarun nan saboda fa'idodinta na gini mai sauƙi da tsattsauran lokaci. Yawancin Gadajen tituna suna da fashe-fashe na bayyane ko ganuwa a cikin ginshiƙan tushe saboda tsayin aikinsu ko aikin ɗaukar nauyi na dogon lokaci. Don fashe-fashe na gaba ɗaya, yawancin amfani da kayan ƙarfafa kayan fiber carbon na iya zama. Gidan ƙarfafawa mai zuwa zai gabatar da aikin ƙarfafa ginin fiber carbon fiber don fasa gada.

Fasahar gini na ƙarfafa kyallen fiber carbon don fasa gada yana da manyan matakai guda uku masu zuwa:

Mataki na farko shine warware layin ƙasa na gadar babbar hanya

1. Gyara structural fasa na manne grouting babbar hanya gada biams tare da fasa.

2. Kawar da gurɓataccen matsayi na saman kankare, kamar zubarwa, sako-sako, siffar saƙar zuma da zaizayar ƙasa, da aiwatar da tsaftacewa, niƙa da goge goge. Bayan saman ya bushe kuma ya fusata, gyara madaidaicin madaidaicin matsayi na simintin da aka gyara tare da kayan aikin gyarawa. Idan akwai m gefuna, yi amfani da takarda yashi don yin kwalliya da goge. Nemo shirin taɓawa hannu ji bushewa, zai iya aiwatar da aikin na gaba na ginin injiniya.

3. Yin da Yang Angle na manna fiber carbon fiber ya kamata a goge shi zuwa siffar baka, kuma a sanya layin Yin Angle ya zama fillet na baka don gyara kayan datti, kuma baka rabin meridian kada ya zama ƙasa da ƙasa. 25mm ku.

Mataki na biyu, goge tushen manne

1, da tura da kyau substrate ya kamata a yi amfani da nan da nan, tare da yarwa taushi goga ko musamman sanya abin nadi za a ko'ina shafa substrate a saman kankare, kada yayyo goga, kwarara ko kumfa. Bincika saman manne bayan tushen manne ya bushe kuma yana da ƙarfi. Idan saman manne yana da ƙullun gefuna, yi amfani da yashi mai yashi don gogewa da gogewa da kyau. Idan manne ya lalace, ya kamata a sake goge shi kuma ana iya aiwatar da tsari na gaba bayan bushewa da ƙarfi.

2. Ya kamata a aiwatar da tsarin fasaha na gaba da wuri-wuri bayan manne tushe ya bushe kuma yana da ƙarfi. Idan lokacin gogewa ya wuce 7d, yakamata a cire manne tushe na asali a fili tare da injin gogewa sannan a sake gogewa.

Mataki na uku, katako mai tushe na babbar hanyar gada ya lika kyalle mai ƙarfafa fasahar gini da kuma matsalolin gama gari

1. Bai dace da aikin injiniya ba a cikin kwanakin damina ko ƙarƙashin damp gas da yanayin sanyi. Idan ya zama dole a yi aiki a kan mambobi masu rigar rigar da sanyi, tabbatar da bushe saman saman membobin da aka riga aka tsara ko amfani da manne ƙwararru.

2, carbon fiber zane manna ya kamata a za'ayi a karkashin aiki zafin jiki misali na 5 ~ 35 ℃, da amfani da m ya kamata saduwa da bukatun na aikace-aikace na aiki zafin jiki.

3. A kan simintin simintin da za a ƙarfafa, za a yi ginin da kuma ɗagawa bisa ga zanen zane, kuma za a bayyana matsayi na kowane nau'i na fiber polymer abu.

4. Yanke zanen fiber carbon bisa ga ƙayyadaddun tsarin ƙira. Tsawon cinyar carbon fiber polymer ƙarfafawa bai dace da ƙasa da 100 mm ba, kuma wurin cinya na ƙarfafa ƙarfe ya kamata ya guje wa yanki mai ɗaukar maɓalli. Dole ne a sanya masana'anta da aka yanke da kyau a cikin diski kuma a ƙidaya su. Ya kamata a yi amfani da kayan polymer fiber da aka yanke da wuri-wuri.

5. Kafin manna zanen fiber carbon, sake goge saman kankare don tabbatar da cewa saman manna yana haifar da ƙura. Lokacin da ake goge manne a saman siminti, maganin colloidal bai kamata ya gudana ba; Maganin Colloid goge fitar da kar a sarrafa layin; Goge daidai gwargwado.

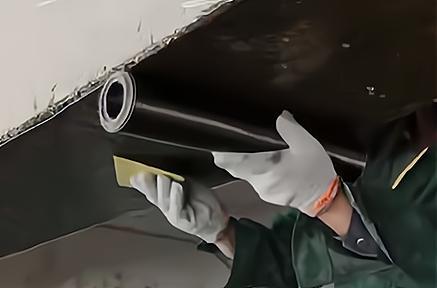

6, manna a cikin sinadarai fiber polymer abu, ya kamata a za'ayi daidai da tsari na Yunƙurin. Ana fitar da zanen fiber carbon daga wannan ƙarshen zuwa wancan tare da ganga na nadi don cire kumfa tsakanin maganin colloidal da sinadarai na fiber polymer, ta yadda maganin colloidal ya shiga cikin sinadari na fiber polymer abu, m da santsi. Ganga da aka yi amfani da shi bai kamata ya haifar da tasirin electrostatic ba a cikin dukan tsarin extrusion.

7, wanda aka zaɓa tare da tube da yawa ko Layer biyu na kayan ƙarfafa kayan fiber polymer, a cikin tsohon Layer na fiber zane surface taɓa yatsunsu ya bushe, nan da nan mai rufaffen manna mai rufi bayan Layer na kayan fiber polymer.

8, karshe Layer na sinadaran fiber polymer kayan aikin injiniya yi da aka kammala, a kan surface na symmetrical shafa Layer na shigar azzakari cikin farji resin epoxy (a overall surface Layer aminci.

https://www.heatresistcloth.com/carbon-fiber-fabric/

Lokacin aikawa: Afrilu-18-2023